News

- All

- Business

- Uncategorized

April – Market and Base Oil Updates

OUR OBSERVATION Dear Readers, April has rolled in with no shortage of excitement in the base oil world. Between spring maintenance season kicking into high gear, ongoing logistical headaches, and shifting export activity that’s more strategic than surprising, the market’s had more than its fair share of moving parts. Buyers and sellers alike are adapting to a push-pull of tightening supply in some regions and cautious buying behavior in others. As always, we’re here to break it down and keep things digestible. In this issue, we explore what’s been stirring in the North American market and peek at how international trends are weaving into the bigger picture. Let’s get into it. Market Overview It’s been a whirlwind month for the base oil market. Across North America, a handful of planned and unplanned refinery outages sent ripples through the supply chain. Some Group I production units were already running lean before April, but the added strain from seasonal maintenance has made availability even more sporadic. Bright stock, in particular, remains hard to come by, especially with consistent demand from West Africa and Latin America putting extra pressure on export volumes. Meanwhile, Group II markets are stuck in a bit of a […]

April – Fueling the Future: Monthly Insights on Crude, Bunkers & Beyond

Dear Readers, With the arrival of spring, the oil markets are anything but thawing. Inventory builds, demand jitters, and unsteady global supply management have all collided this April to stir the pot. As always, we’re bringing you the facts—with just the right amount of fun. Let’s dig into the latest from the world of fuel, from tank tops to tanker ships. Crude Oil Market Overview Crude oil inventories have been quietly stacking up over the last few weeks, climbing more than 9 million barrels since mid-March to reach 442.9 million barrels by April 11. Despite this build, stocks remain 4–6% below the five-year average, reflecting long-term tightness even as short-term surpluses emerge. Refinery utilization stayed firm between 86–87%, with inputs averaging just under 15.7 million bpd, signaling a smooth post-turnaround ramp-up. Meanwhile, imports stayed soft—averaging just above 6 million bpd, down 5–11% year over year, giving domestic producers more space to fill the gap. Gasoline demand didn’t help matters: it was down 3.4% YoY, contributing to falling inventories. Jet fuel was the star of the show, with 9.1% YoY growth, while distillates held steady with a 7.1% bump over last year—pointing to consistent industrial and freight activity. Globally, the situation […]

How Tariffs and Duties Impact Base Oil Pricing—and How Signal Fluid Solutions Helps You Avoid Extra Costs

Tariffs, duties, and customs regulations have a major impact on the cost of specialty base oils and lubricants—both at the supplier level and in your final delivered price. Understanding how international trade policies, especially under the United States-Mexico-Canada Agreement (USMCA), affect these costs is critical for lubricant manufacturers, distributors, and industrial buyers. Recently, the U.S. administration has increased duties on select Canadian energy imports that do not meet USMCA compliance, further raising operating costs for lubricant producers across North America. Here’s what you need to know—and how partnering with a knowledgeable, USMCA-compliant base oil supplier like Signal Fluid Solutions can help protect your margins. New Tariffs on Canadian Energy Imports: What Changed? In March 2025, the Independent Lubricant Manufacturers Association (ILMA) shared new guidance from U.S. Customs and Border Protection (CBP) related to Canadian petroleum imports. While certain refined petroleum products now qualify for a reduced 10% duty under USMCA, many raw materials, such as petroleum-based lubricating oils (classified under Heading 27 of the Harmonized Tariff Schedule of the United States), remain subject to a 25% tariff if they fail to meet USMCA’s strict rules of origin. Examples of Energy Resources Potentially Facing Extra Duties: Hydrocarbon mixtures (less than 50% […]

March – Fueling the Future: Monthly Insights on Crude, Bunkers & Beyond

Dear Readers, Spring is here, and while the flowers are blooming, the energy markets are still trying to find their rhythm. Crude oil supplies are building, bunker fuel markets are adapting to new regulations, and fuel oil trade flows are shifting in unexpected ways. This month, we break it all down in a way that’s easy to digest—because let’s be honest, oil markets may be complex, but they don’t have to be boring! Crude Oil Market Overview Crude oil prices have been on a bit of a rollercoaster, with Brent hovering around $70 per barrel as supply continues to outweigh demand. U.S. crude oil inventories climbed to 437 million barrels, keeping stockpiles about 5% below the five-year average. Meanwhile, refineries are back in action post maintenance, running at 86.9% capacity as they gear up for the summer driving season But here’s the kicker—imports are down 11% from last year, meaning we’re relying more on domestic production to keep things moving. And while global demand is still growing, it’s not exactly surging, with the IEA predicting a 1.0 million bpd increase in 2025, mainly thanks to China’s booming petrochemical sector. Bunker Fuel Insights The bunker fuel market is holding steady, but […]

February – Market and Base Oil Updates

OUR OBSERVATION Dear Readers, Since our last newsletter, we have seen continued shifts in the North American base oil market, influenced by tightening supply conditions, shifting global trade flows, and ongoing refinery maintenance schedules. As we navigate these evolving dynamics, market participants remain focused on balancing inventory levels, mitigating supply chain disruptions, and adjusting to changing crude oil trends. This month’s insights provide an in-depth look at these developments, along with key headlines and industry trends that are shaping the base oil landscape. Market Overview The North American base oil market navigated a complex landscape in February, marked by tightening supplies, shifting demand patterns, and geopolitical pressures affecting global trade. Group I base oils continued to experience constrained availability, particularly bright stock, as refiners allocated limited production toward higher-value products. Group II markets remained steady overall, with refiners preparing for upcoming maintenance turnarounds that could affect availability in the coming months. Group III oils, meanwhile, saw continued firm demand, particularly in the automotive and industrial lubricant sectors, where supply constraints persisted. The U.S. market faced logistical challenges, with increased transportation costs and shipping delays affecting domestic distribution. Some refiners prioritized exports to Latin America and Asia, where demand remained strong […]

February – Fueling the Future: Monthly Insights on Crude, Bunkers & Beyond

Dear Readers, As we navigate through February 2025, the energy landscape remains in flux, shaped by shifting market conditions, policy shifts, and global economic influences. The balance between supply and demand continues to evolve, with refinery operations, inventory trends, and geopolitical events all playing a role in shaping the outlook. In this edition of Fueling the Future, we take a closer look at the latest movements in crude oil, bunker fuel, and fuel oil markets, uncovering key developments and what they mean for the months ahead. Crude Oil Market Overview Current Trends: Refinery Adjustments: Refinery activity remained stable through mid February, with U.S. crude oil refinery inputs averaging 15.4 million barrels per day (bpd). Refinery utilization held near 85%, reflecting a typical seasonal maintenance period. Inventories Tighten: However, inventories saw a noticeable increase, climbing to 432.5 million barrels, about 3% below the five-year average. This build-up, combined with declining imports—falling from 6.9 million bpd in late January to 5.8 million bpd by mid-February—suggests that domestic supply remains resilient despite external uncertainties. Looking Ahead: Looking ahead, OPEC has reaffirmed its global oil demand growth forecast at 1.45 million bpd for 2025, maintaining confidence in a steady recovery. However, geopolitical tensions, particularly […]

Beyond Bulk Oil Supply: 5 Benefits of Packaged Process Oils

In the world of thermoplastic elastomer (TPE) manufacturing, where precision and reliability are paramount, process oils play a vital role in ensuring consistent product quality and operational efficiency. Yet, how those oils are delivered can be just as critical. For some businesses using process oils to manufacture TPEs and other products, partnering with a supplier that offers packaged options, like drums and totes, can provide significant advantages. What Are Packaged Process Oils? Unlike bulk deliveries, which require large tanks and additional equipment, packaged oils provide a flexible and secure solution tailored to your needs. Packaged process oils come in convenient, manageable containers, such as 55-gallon drums or 275- to 330-gallon totes. These containers are designed to make storage, handling, and usage easier, particularly for companies with limited space or specific production requirements. Why Packaged Process Oils May Make Sense for Your Business At Signal Fluid Solutions, we understand that every operation is unique. That’s why we’re committed to offering flexible solutions, including packaged process oils. Here are some of the key benefits: 1. Easier Storage and Space Optimization Not every facility is equipped to handle bulk oil storage. Packaged options like drums and totes offer a compact, stackable solution, making it easier […]

January – Fueling the Future: Monthly Insights on Crude, Bunkers & Beyond

Dear Readers, Welcome to the January 2025 edition of Fueling the Future, where we explore the latest shifts in the U.S. fuel oil, bunker fuel, and crude oil markets. With the start of a new year comes a blend of opportunities and challenges, driven by evolving market dynamics, supply chain adjustments, and global policy shifts. Let’s dive into the key trends and factors shaping the year ahead. Crude Oil Market Overview Current Trends: Refinery Adjustments: U.S. crude refinery inputs in January averaged lower than late 2024 levels, as seasonal maintenance and operational recalibrations took hold. Refinery utilization hovered around 85.9%, reflecting reduced activity from year-end peaks Inventories Tighten: U.S. commercial crude oil inventories remain below the five-year average, underscoring ongoing tightness despite an uptick in imports. Distillate inventories are also trending lower, amplifying concerns over regional supply shortages heading into Q1 . Looking Ahead: The signs point to a market in transition. While production remains resilient, logistical challenges and policy shifts may tighten crude availability, particularly as export demand remains robust. Balancing domestic supply priorities with growing international needs will be key for refiners and producers. Bunker Fuel Insights Market Dynamics: Weather Disruptions: January’s harsh winter conditions created delays in […]

January – Market and Base Oil Updates

OUR OBSERVATION Dear Readers, Welcome to our January 2025 edition, with a stronger focus on North America. We’ll explore the latest developments shaping the U.S. base oil markets while briefly highlighting key international dynamics. Dive into this month’s insights, curated headlines, and a deeper spotlight feature. Market Overview The North American base oil market began 2025 with signs of stabilization amidst seasonal adjustments. Group II refiners implemented minor operational adjustments as they managed inventories ahead of Q2 maintenance schedules. With steady demand across most Group II grades, producers have focused on balancing supply to avoid significant overhangs. Group III oils, however, have seen incremental price increases due to limited domestic production and firm demand from both automotive and industrial sectors. Refiners in the U.S. Gulf Coast are adjusting their output strategies to capitalize on export opportunities to Latin America and South Asia, while maintaining a reliable flow to domestic buyers. In addition, broader economic signals, such as inflationary pressures and global supply chain adjustments, have influenced procurement strategies. The U.S. continues to serve as a critical hub for Group I export activity, supported by relatively stable feedstock pricing. As we progress into Q1, the focus remains on inventory optimization and […]

5 Key Benefits of Using Natural Ester-Based Transformer Oils Like FR3

In the ever-evolving energy industry, choosing the right transformer oil can make all the difference. Natural ester-based oils like FR3 are quickly becoming the go-to choice for utilities and manufacturers worldwide. Here’s why: 1️⃣ Eco-Friendly: Made from renewable plant-based materials, FR3 is biodegradable and non-toxic, reducing environmental impact. 2️⃣ Fire Safety: With a high flash and fire point, FR3 significantly reduces the risk of fire, offering a safer solution for critical applications. 3️⃣ Extended Equipment Life: FR3 oil enhances the life of paper insulation in transformers, which can result in a longer overall lifespan for your equipment. 4️⃣ Improved Performance in Extreme Conditions: FR3 performs reliably under tough conditions, like high heat, ensuring uninterrupted operations. 5️⃣ Sustainability Incentives: Many industries are embracing sustainable practices, and FR3 aligns perfectly with corporate and regulatory goals for reducing carbon footprints. 💡Ready to make the switch to FR3? Let us help you enhance safety, efficiency, and sustainability in your operations. Contact us today to learn more about FR3 and how it can transform your energy solutions!

Inside the Push for Oil Industry Sustainability: 4 Key Strategies

Oil industry sustainability is a major goal for companies like Chevron and Shell. These industry leaders are wielding their resources to create a more eco-friendly future in the ever-evolving energy space. Shell CEO Wael Sawan has outlined the strategy for the industry: “The energy and cost of living crises have highlighted the need for a balanced energy transition: one in which the world achieves net-zero emissions, while still providing a secure and affordable supply of energy.” Read on to learn more about the strategies these world leaders in the oil and gas industry use to create a greener world. 1. Investing in Low-Carbon Technologies Oil and gas companies are increasing their focus on clean energy avenues by investing directly in low-carbon fuels and technologies. Their investment helps fuel the next wave of clean, environmentally friendly tech and provides a means to shift their business towards a more sustainable model. For example, according to Forbes, ExxonMobil has begun construction of a lithium production operation. As lithium is a crucial component in the production of electric vehicles, this move positions Exxon to take advantage of, rather than fear, an increasingly electric future. Other oil and gas companies like Shell and TotalEnergies have made large investments […]

Fueling the Future: Monthly Insights on Crude, Bunkers & Beyond

OUR OBSERVATION Hello, energy enthusiasts! As we wrap up 2024, let’s take a light-hearted yet insightful journey through the latest trends in the U.S. fuel oil, bunker fuel, and crude markets. Grab your favorite holiday beverage, and let’s dive in! Crude Oil: A Year in Review This year, crude oil prices have been on a rollercoaster, influenced by global economic indicators and geopolitical events. As of December, Brent crude is trading around $73 per barrel, showing resilience amid market fluctuations. The U.S. Energy Information Administration (EIA) reports that U.S. crude oil production averaged 13.2 million barrels per day in 2024, with projections to reach 13.5 million barrels per day in 2025. U.S. Energy Information Administration Fuel Oil: Steady as She Goes The fuel oil market has maintained relative stability throughout December. Notably, the ARA (Amsterdam-Rotterdam-Antwerp) region’s independently held fuel oil stocks have increased by 5% compared to November, indicating a balanced supply-demand scenario. Manifold Times Bunker Fuel: Navigating the Currents In the maritime sector, bunker fuel prices have experienced adjustments due to crude oil market fluctuations. For instance, Transfennica announced an increase in their Bunker Fuel Surcharge from 7.1% in November to 9.1% effective December 1, 2024. Transfennica Market Dynamics […]

December – Market and Base Oil Updates

OUR OBSERVATION Hello, oil aficionados! As the holiday lights flicker and the year winds down, let’s cruise through the latest waves in the base oil markets across the globe. Whether you are crunching numbers by the fireplace or strategizing for 2025, this edition will keep things smooth, insightful, and easy to digest. Market Overview – Holding Steady with a Few Twists December’s base oil landscape painted a picture of stability, albeit with slight price dips here and there. The market slowdown ahead of the holiday season played a key role, as players kept inventories lean and transactions light. In the US market, spot discussions were minimal, and market activity cooled as suppliers held back larger volumes. This calm allowed prices to remain largely unchanged. Meanwhile, in Europe, a reduction in imports balanced weaker demand, keeping pricing relatively stable. Across Asia-Pacific, the seasonal slowdown tightened its grip, leading to minimal bulk offers. However, Group I shortages eased, thanks to recent supplies from Thailand, Japan, and Indonesia. Regional Breakdown – What’s Moving and What’s Not US • No surprises here – US Group I and II prices held firm. • Naphthenics showed slight softening, with pale oils down by $5-9/t. Europe • […]

October – Market and Base Oil Updates

OUR OBSERVATION Readers, I hope this newsletter finds you well. Since our last newsletter in late August, we have seen reductions for key US Refiners on GI, GII & GIII products ranging from ($0.10) CPG on the low to ($0.50) CPG on the high. Suggesting they are trying to bring relevance back to posted pricing. Despite price reductions there still appears to be a gap between domestic posting’s, market, and export pricing. One of the key drivers of the gap appears to be driven by softer demand. We in fact forecasted such for the 4th quarter and is generally in sync with normal seasonal slowdowns. We do feel there are a few more factors at play other than just a seasonal slowdown, however. The USA and abroad have seen many market sectors showing signs of economic slowness. Witnessing announcements made by major retailers of shutting doors or going into bankruptcies has been sobering driven by consumers’ lack of spending compounded by higher interest rate debt continues to weigh in on our economy. Meanwhile even with a few close Hurricane calls, the market will soon have to burn off the extensive hurricane buildup which will be spilling back into the marketplace. […]

4 Ways The Right Process Oil Can Benefit Commercial Construction

In many ways, process oils are one of the unsung heroes of commercial construction, as they improve efficiency in the production of a wide variety of important building materials. The process oils used in the production of synthetic rubber products like TPEs (thermoplastic elastomers) and EPDM products play a crucial role in everything from the parking lot to the roofing system. Quality process oils are important in ensuring that rubber products: Maintain their shape and surface quality Resist discoloration Remain flexible Withstand weather and UV exposure Here are some of the ways that process oils and their derivatives are crucial for the construction industry. 1. Parking Lots Most commercial builders elect to pave their parking lots with asphalt because of its cost-effective longevity. But after a few years of heavy use and exposure to the elements, even asphalt will crack, and eventually, businesses will be responsible for expensive and disruptive repairs. One solution for this problem is the addition of rubber polymers to the asphalt. This further increases its flexibility and resistance to cracking, extending its useful life. Polymer-modified asphalts are especially useful for applications like parking lots with heavy traffic. However, even these polymers can stiffen due to evaporation of […]

Top 5 Specialty Oil Trends: Diverse Applications for the 21st Century

The oil business has never been as interesting as it is today, as the 21st century brings new advances in technology, sustainability, and applications of specialty oil. We’re watching several trends, including: Immersion cooling oil in high-performance computing and electric vehicles Agricultural applications of natural gas-to-liquid oils (isoparaffins) Growing demand for recycled and re-refined oil Custom polymers made with specialty process oils for the medical industry Bio-based specialty oil for thermoplastic elastomers (TPEs) Multiple industries are driving the development of new specialty oils to support innovation. These are some of the trends to watch over the next decade. 1. Specialty Oil for Immersion Cooling in Data Centers and Electric Vehicles The rapid increase in global data usage, projected to reach 180 zettabytes by 2025, is driven by advances in data-driven technology and the growing number of internet users. This surge in data has heightened the demand for efficient cooling solutions, as traditional air cooling methods struggle to keep up with the heat generated by powerful servers in data centers. Immersion cooling oils, developed through gas-to-liquid (GTL) technology, offer a more efficient, simple, and sustainable alternative. These oils are particularly beneficial for data centers, cryptocurrency mining, and electric vehicles, providing superior cooling, […]

August – Market and Base Oil Updates

OUR OBSERVATION Readers, I hope this newsletter finds you well. Since our last Newsletter mid-July, we have not seen any key US postings changes up or down by any of the major base oil producers suggesting they are still analyzing market conditions while grappling with the disconnect between prices on the street vs postings. GII “Market” price for 220 & 600 dropped between 8 & 9 CPG. We know there is still tightness on the 100 & 600 however this is being outpaced by lower demand of the two grades. 220 still seems to be long to balanced depending upon what producer you speak with. Inclusive of this a key base oil refiner will be entering turnarounds for the remainder of this year and beginning of 1st quarter 2025. Production of 600 Is projected to be flush after the turnarounds are finished. We have seen Re-Refined gal’s creep into the markets where tightness of virgin GII was projected so much so a key Re-Refiner has sold most of its surplus of 100. Asian GII Arb barrels have seemed to slow due to the rising costs of logistics and the lower premiums for the US markets. Most Asian barrels are being […]

July – Market & Base Oil Updates

OUR OBSERVATION Readers, I hope this newsletter finds you well. Since our last Newsletter back in early June, we have not seen any key US posting changes up or down by any of the major base oil producers suggesting they are still analyzing market conditions while grappling with the disconnect between prices on the street vs postings. GII “Export” Pricing did move however with a small 5 CPG increase on 100 & 600 vis grades recently. This appears to support a clearing of the overhang for now. However, there is noise coming from across the pond. Asia base oil stockpiles have risen with recent lowering in demand from China which supports some key producers thinking that this overhang of supply may bleed back into the market at some point in the future. Some feel this overhang will splash back on US Soil late 3rd Qtr to 4th Qtr this year. As we learn more we will report. Meanwhile, two major GII US producers have corrected their production hiccups on the 100 Vis range which means and improvement in supply for the near term. The Recent hurricane Beryl did cause some Terminal Disruptions in the last few weeks yet thankfully only […]

The Best of Both Worlds: A New Source for High Solvency, Color-Stable Process Oil

Achieving color stability is a crucial challenge in the world of engineering lightly-colored thermoplastic elastomers (TPEs). But product-specific applications come with many other requirements as well. For example, low volatility may be required to keep extender oils from evaporating under high heat, or rubber compatibility may be important for extending volume in EPDM (ethylene propylene diene monomer) products. Engineers can find it difficult to find process oils that are both highly solvent (typically naphthenic) and color stable (typically paraffinic). Thankfully, a new process oil option is helping engineers find the “sweet spot” for their applications. Paraffinic and Naphthenic Process Oils Paraffinic process oils are commonly used as extenders in TPE and EPDM products. They have low aromatic content and are relatively inert. This contributes to their soft-touch and color stability, highly desirable for products like footwear and automotive interior moldings. Low volatility gives paraffinic oil a lower risk of mobility and offgassing, maintaining suppleness for the life of the product. In addition to those mentioned above, applications for these oils include: insulation, textiles, furniture polish, weather stripping, and many more. Naphthenic oils are generally not so color-stable. The trade-off for using naphthenic oils is that they have a higher solvency, especially when dissolving polar materials. This […]

April – Market & Base Oil Updates

Since our last newsletter, we witnessed the GI & GII and some GIII postings space move during late February, March, and April 1st, for one key GII refiner. These increases ranged from 15-20 cpg$. As of this writing we are now seeing the GI & GII space announce further price increases within the 30-40 cpg$ range as we wait for others to follow. Big Blue opted out of the first round of postings increases in Feb/March and we have not heard any news as to today’s position. We will report as we learn from others as well. All Refiners are claiming that Crude, NG and VGO Feedstocks are on the rise. And they are correct. Since Mid-March, Crude is up another 9.8%. VGO is up another 8.35% while Natural Gas is up 8.7%. ULSD creeped up another 4% on the lag. And let us not forget our ULSD alternate competitor within the refinery as well. So, when ULSD garners more profit, it is given more VGO feedstock until Base Oils improves their profit stream. It is one of the internal battles that is constantly in play. These verifiable production cost pressures are bubbling up within all the refining sectors. 3:2:1 […]

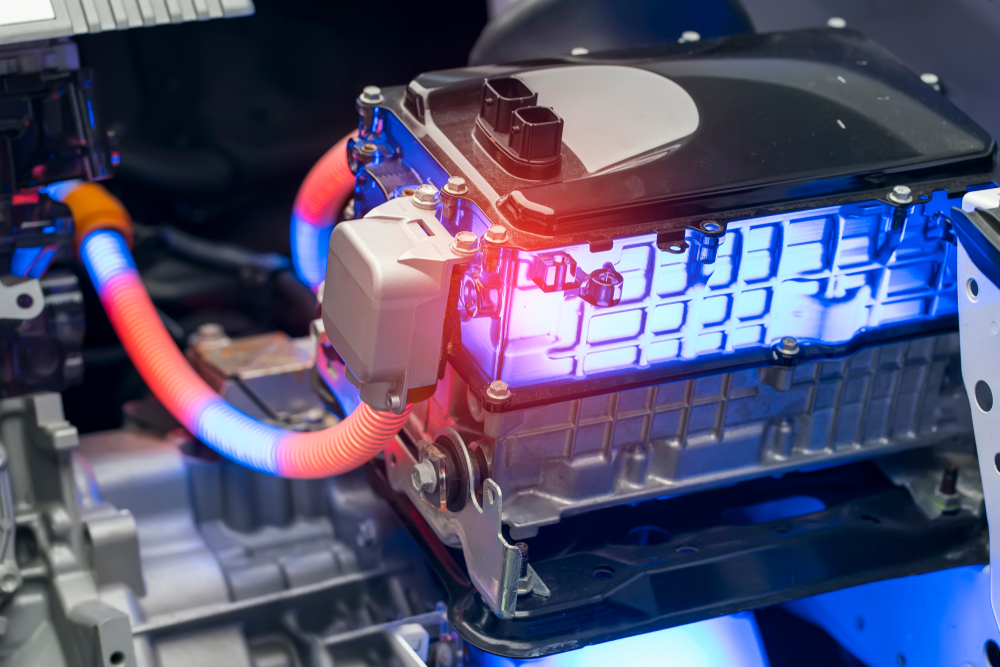

Grease Industry Outlook: The Effect of Electric Vehicles on Base Oil Selection

In 2022, the grease industry’s international value was estimated at $3.7 billion, and by 2029 this number is expected to reach $4.7 billion. This tracks closely with the projected increase in volume, especially in the Asia-Pacific region, from 2.62 billion liters in 2024 to 3.08 billion by 2029, growing at a compound annual rate of 3.38 percent. But even though the grease industry—with diverse lubricant applications from household products to heavy machinery—is set to expand, it must respond to major trends in one of its primary markets: the automobile industry. The Rise of Electric Vehicles The electric vehicles market has gone from a niche, futuristic concept to everyday reality very quickly. While in 2021 only 3.4 percent of new cars sold were electric vehicles, by 2030, that number will likely be close to 30 percent. This is partly due to growing consumer demand for sustainable alternatives to traditional gasoline-powered automobiles. But it also has the force of regulatory pushes behind it, like the initiative enacted by the state of California, which has mandated that by 2035 all new cars sold within the state must be zero-emission vehicles. Likewise, China, one of the largest and fastest-growing markets for automobiles, has imposed a policy that […]

Thermoplastic Elastomers vs. Natural Rubber: Adaptable Polymers and the Role of TPE Process Oil

The thermoplastic elastomer (TPE) industry is growing faster than ever, projected to grow from about 10 million metric tons in 2025 at a rate of 5% throughout the decade. This is not surprising when you take into account the numerous industries in which TPEs play a part. Their many advantages make them perfect for applications in: Hand and power tools, Automotive, Houseware and appliances, Medical applications, Fire retardants, and many more. What is it about TPEs specifically that makes them so well suited for such a wide array of products? The Origin And Development of TPEs In 1926, Waldo Lonsbury Semon, a chemist working in Ohio, invented plasticized polyvinyl chloride (PVC). Plasticized PVC was softer, and more flexible than non-plasticized PVC had been, and its discovery opened the door for further research into how to create a new kind of plastic. The goal was to combine the characteristics of elastomers like rubber, which are stretchable, flexible, and soft, with plastics, which can be melted and shaped easily and have greater processing efficiency. Scientists across the world began working towards this goal. The first class of TPEs to hit the market, thermoplastic polyurethane polymers, came on the scene around 1950 and were quickly integrated into a […]

Looking for a Process Oil Supplier? Use These 3 Criteria

Process oils are used in a wide variety of applications, including extender oils which soften TPEs (thermoplastic elastomers) and EPDM (ethylene propylene diene monomer) rubbers, which make up many of the products consumers use every day. For businesses that require oils like these in their products, finding the right process oil supplier is one of the best ways to ensure quality, avoid logistical headaches, and even improve your bottom line. But where do you start? Knowing the right details to look for is the first step towards choosing the process oil supplier that’s the best fit for your company. Here are some of the most important criteria to look for in any supplier. 1. Product Quality Assurance First and foremost, determine whether you can rely on consistent product quality from your process oil supplier. For most applications, your process oils should have the following characteristics: Stability, Low-volatility, Odorless, and Excellent compatibility to prevent blooming It’s important to work with suppliers who provide ingredients that meet necessary quality standards consistently. How can you ensure consistent product quality from a supplier? One way is to look into what kind of processes they use, and what certifications they have. For example, a widely recognized indication that a business […]

February 2024 – Market & Base Oil Updates

To all we hope this Market update finds you well. Let me start by saying the markets and market intel have been very fluid and dynamic. Clearly sending mixed signals from one week to the next. We are being careful to not update via an everyday play by play, but allowing more time in between multiple events helping to create a clearer read into the market trends. 2023 was an interesting year where we witnessed some interesting factors at play. Some appearing to be in direct conflict with the other. We digress. Crude Oil Cost traded in a very tight band width in 2023 with only a few exciting months all while we had a relatively balanced Base Oil supply situation with very strong pricing firmness. The pricing firmness on the base oil was a direct result of having to compete within the refinery against very strong Diesel Fuel Sales & Margins. Not all things last forever as we all well know. A more interesting fact is that 2023 proved to be the lowest Lubricant production year since 1997. A demand slump stimulated by a slowing global economy brought on by too many factors to list here, but all were […]

5 Ways to Cut Costs: Lessons from Specialty Oil Supply Logistics

A chain is only as strong as its weakest link, and your business is only as good as your raw materials supply chain. Principles from specialty oil supply logistics can strengthen it. Some of the following tips are specific to liquid raw material transportation. But some concepts are universal. Consider asking your supply partners whether they use any of these practices to bring down supply chain costs. 1. Inventory Management Given how unstable global supply chains have been throughout the pandemic, it’s never been more important to stock up and maintain a healthy inventory. Of course, the downside is the added “carrying cost” of maintaining a warehouse. This can be as much as 30 percent of your total inventory value. By outsourcing inventory management to a stocking supplier, a.k.a. two-step distributor, you can reduce or even eliminate your own carrying costs. (Signal Fluid Solutions also maintains these inventories at locations throughout the U.S., cutting down transportation time as well.) 2. Terminal Efficiency Inefficiencies in the transport of key raw materials are often considered a necessary cost of doing business. But suppliers can do a lot to mitigate delays and shorten delivery windows. For example, it’s not uncommon for specialty oil trucks to […]

Immersion Cooling Is the Future of Computing: How to Prepare Your Supply Chain

Advancements in computing technology demand that it runs ever faster and hotter. In turn, the immersion cooling market is poised for incredible growth. Valued at $302M worldwide as of 2022, the market is expected to grow at a whopping 24.2% CAGR (compound annual growth rate) to reach $1.71B by 2030. What’s driving this? High-performance computing for artificial intelligence Data mining for cryptocurrency Electric vehicle processors and batteries Advancements like these are driving manufacturers across several industries, such as automotive and industrial lubricants, to invest heavily in immersion cooling products. Is your supply chain ready? The Computing World Is Leaning Into Immersion Cooling As the heat generated from high-performance computing and power supply increases, air-cooling cannot keep up. Highly-refined, dielectric mineral oils and liquid natural gas derivatives are evolving into good options for immersion cooling. NVIDIA, AMD, Intel Advances in generative AI (artificial intelligence) are pushing the biggest names in computing to develop new software and hardware to support the computing demand. Air cooling has traditionally been an inexpensive and simple method to prevent overheating of the data centers that house graphics processing units (GPUs) like NVIDIA’s H100 GPU with 80,000 transistors. But as demand for image-generating AI increases, air cooling units are getting overtaxed. […]

How High-Viscosity White Oil Can Improve Vehicle Interior Air Quality (VIAQ)

In the automotive industry, the choice of high-viscosity white oil used in the production of cabin interiors matters for many reasons. Chief among them is consumer health. The release of chemicals, including volatile organic compounds (VOCs), into the interior air that drivers breathe every day is a serious health concern. Inferior process oils can be part of the problem. But thermoplastic elastomer (TPE) manufacturers, in partnership with their high-viscosity white oil supply partners, are making great progress toward solving it. Can VOCs Cause Cancer? It’s been common knowledge for years that the chemicals released from interior components, which together produce that “new car smell,” aren’t exactly good for people to inhale. Just how dangerous they are remains a subject of research. In a summer 2022 study, researchers in Beijing took interior air samples of a mid-size SUV (sport-utility vehicle) manufactured once month prior over a 12-day period. As reported by journalist Bruce Y. Lee in Forbes, they found elevated levels of benzene and concentrations of formaldehyde and acetaldehyde in the interior air that were, respectively, 34.9% and 60.5% above Chinese national safety standards. “Formaldehyde and benzene … are considered class I carcinogens by the International Agency for Research on Cancer (IARC), meaning that they are […]

How Specialty Oil Suppliers Are Pivoting to Support the Future Automotive Industry

The internal combustion engine (ICE) is starting to give way to electric vehicles (EV) in terms of market share, and specialty oil suppliers are watching the shift closely. Oil suppliers have long provided base products to lubricant makers. Now, the industry is beginning to invest more heavily in dielectric battery coolant fluids to support EVs. For those of us in the oil industry, it’s important to think about how to prepare for this shift. Here’s a quick overview of where we are and how we’re preparing to evolve. Evolve and Prosper: Specialty Oil Suppliers and Buyers Lubricant companies are focusing more heavily than ever on thermal management fluids as a means to future-proof the industry. EV fluid is developing into a highly competitive market. “I think we realized that in the future the battery of a car will be almost what the engine was in the past … So it will be a center point of future mobility.” – Matthias Ostertag, Head of Global Business Segments, Fuchs Lubricants Specialty oil suppliers like us want to be there for our customers in support of the shift. Thankfully, there’s enough precedent in specialty oils that we’re not starting from scratch. Inspiration from Legacy […]

Naphthenic Process Oil Supplier Expanding Access Amid Ongoing Supply Chain Disruptions

Global supply chains continue to face significant disruptions compared with the pre-pandemic world, and process oil suppliers are no exception. Shortages of select specialty oils used in the production of synthetic rubbers, sealants, and adhesives continue to plague the market. Process oil suppliers must rise to the challenge of filling these strategic gaps to maintain the momentum of these growing industries. (One solution we discuss below: developing new products like our Renoil 500-X.) Process Oil Suppliers and Post-Pandemic Supply Disruptions Supply chains today are experiencing critical gaps in product availability due to a number of ongoing threats, such as: Geopolitical tensions. As the war in Ukraine continues, cooperation between governments allied with opposing parties is increasingly tedious. End users and suppliers must practice “friend-shoring” (looking for new trade partners as a fallback) or risk losing access to critical raw materials. Cyber attacks. Cybercriminals are compounding the problem of scarcity by hacking into supply chain networks to steal data, hold data for ransom, or cause other types of disruptions. Suppliers can mitigate this risk by tightening supply chains, partnering with trusted, secure vendors, and supplying original products directly to customers. Rising costs. Select products are rising in price as transportation costs increase and supply chains fail to support […]

Paraffinic, Naphthenic, Aromatic: How Rubber Process Oil Suppliers Hit the “Sweet” Spot

Process oil suppliers traditionally place most products into one of three categories, but these traditional indicators of color stability don’t always tell the whole story. In general, these categories cover the spectrum of desired qualities for use in rubber, EPDM and TPE (thermoplastic elastomer) manufacturing: Aromatic – dark, low color stability, great solvency Naphthenic – lighter in color, varying stability, intermediate solvency Paraffinic – lightest in color, high color stability, inert But for certain end products, engineers need to consult with process oil suppliers to consider unique solutions. Only the right mixture of characteristics will hit the “sweet” spot. The Challenge of Finding the “Sweet” Spot When selecting an appropriate extender, product engineers can choose from a variety of process oil products for certain end products within the proper category. Others have more exacting specifications. For these, we need to look beyond category to find the right point on the product spectrum. Matching End Product to Oil Category Examples of end product/process oil category matches that are generally acceptable include: Aromatic When color doesn’t matter, the high reactivity of aromatic process oils are acceptable. These include automobile tires, tread rubber, conveyor belts, and other applications where the color is typically black. (Automotive interiors […]

3 Things to Look for in a Mineral Oil Supplier (or Any Supplier)

When you’re on the lookout for a mineral oil supplier, proximity is just one of many important factors to consider. Looking for a supplier near you is a great start. No supplier (us included!) can be everywhere and serve everyone. But depending on where you need service, you may find a number of options available to you. So how do you choose? Here are a few key qualities to look for. Mineral Oil Suppliers and Other Supply Chains Though our focus is on specialty oil products, the following criteria are important to consider when choosing a supplier for virtually any raw material or production product. Technical Expertise What does product “quality” mean? There are objective, universal standards every supplier needs to meet. These include general characteristics such as consistency and reliability. But in many cases, especially if you’re in a niche industry, a raw material that’s an otherwise “quality” product may not meet the specifications you need for your application. This is where the technical expertise of your supplier is critical. A supplier that delivers an excellent product that’s perfect for the wrong application can do more harm than good. Scenario: They Say They Can Do It A supplier specializes in mineral oils used in the production of […]

Process Oil in Gel Manufacturing: Key Characteristics for Quality Gel Products

In gel manufacturing, no raw material is more important than process oil. Polymers have their role to play. But oil is the definitive ingredient behind quality gel production. Your choice of process oil will determine: Performance characteristics Color stability Safety in production Other key characteristics that vary by product Below, we consider three product category examples to demonstrate the vital importance of process oil in a variety of gel applications. 1. Prosthetics Paraffinic process oils are used in the production of prosthetic products to improve their flexibility and resistance to tearing, ensuring a comfortable and secure fit. Liners and Sleeves In prosthetic limbs, it’s vital that contact points between the amputee’s residual limbs and the prosthetic socket are as comfortable as possible. Liners and sleeves are made with delicate, gentle materials ideal for prolonged contact with skin. Prosthetic gels made from thermoplastic elastomer (TPEs) and TPE medical grade white process oil help to evenly distribute pressure on the socket. Theatrical Prosthetics Properly-formulated silicone gels are ideal for imitating human tissues in theatrical prosthetics, such as altering an actor’s physical features or simulating dramatic injuries. The process oil content in this type of prosthetic makes a difference in comfort and the actor’s ability to work […]

How to Optimize Rail Logistics for Your Supply Chain

Rail logistics is essential to many industries, including specialty oil suppliers like us and the customers we serve. Our industry, and by extension, the industries we serve, depend on rail freight transportation for its cost-effectiveness and other benefits. Rail has its limitations as well. But with an experienced and technology-enhanced approach to rail logistics, you can maximize the efficiency of rail in your supply chain. Why Rail Logistics? Here in North America, seven Class I railroads are in operation: BNSF Canadian National Railway Canadian Pacific CSX Kansas City Southern Norfolk Southern Union Pacific These are the major carriers of rail freight, and each has its own system for tracking the trains that keep the economies of the U.S. and Canada humming. In addition, the U.S. network of railways is extended by 22 regional and 584 (local) short-line railroads, which stretch nearly 140,000 route miles. Industries like ours need to navigate not one but all of these lines to get our products where they need to go. Rail logistics, the science of finding the most efficient route, is a simple enough concept. But the actual practice of rail logistics makes the difference between rail freight transport as a net benefit to your business or a net […]

How Waste Oil Recycling Will Transform the Lubricant Industry This Decade

Consumer demand for eco-friendly products is driving tremendous growth in the waste oil recycling industry. The waste oil market was valued at nearly $67B in 2022 and is projected to surpass $93B by 2028, at a strong CAGR (compound annual growth rate) of 6.02 percent. Stakeholders that include environmental advocacy groups, the federal government, refiners, lubricant manufacturers, and base oil suppliers are taking note. But what exactly can lubricant makers expect from a greater investment in waste oil recycling in the coming years? Why Lubricant Makers Are Embracing Waste Oil Recycling In a December 2020 report to Congress, the U.S. Department of Energy (DOE) detailed many environmental and economic benefits of recycling waste oil. DOE argued that used oil recycling: Advances sustainability by extending the life of U.S. crude oil resources. Protects the environment by reducing the likelihood of soil and water contamination. Conserves energy, “as it can take less energy to recycle used oil than to create new lubricating oil from virgin crude oil.” Helps provide consumers with a range of economical product choices. Lubricant manufacturers are interested in sustainability, efficiency, and marketability, and not just due to the ideological appeal of conservation. These metrics represent returns on investment. It’s the profitability of waste […]

Expanding Process Oil Sourcing for Adhesives, Sealants, and Rubber Manufacturers: Renoil 500-X

Supply security remains a top concern for many industries that rely on specialty oils in manufacturing. In particular, makers of adhesives, sealants, rubbers, and synthetic polymers often have tightly limited options in extender oil sourcing. Any specialty process oil with only a single source in the market represents a supply chain risk that makes manufacturers understandably anxious. One such product is a highly refined naphthenic process oil. Essential in the production of select products, this product has only been readily available from one supplier. Signal Fluid Solutions is now supplying the market with a viable alternative: Renoil 500-X. Ongoing Supply Chain Woes At the time of writing, snags in supply chains are affecting the availability of just about everything. Cars, computer chips, furniture, and of course, crude and specialty oil products. As reported in the New York Times on January 12, 2022: “Despite some predictions that supply chain woes would dissipate, many businesses appear to have seen little improvement in supply chain problems that continue to raise costs and spill over into higher sticker prices. ‘Much of the tumultuous nature of the supply chain that occurred over the entire last year continues, and unfortunately there is not a lot of relief in sight,’ said Douglas Kent, […]

How Would a Rail Strike Affect Specialty Oil Supply Security? Strikes In U.S. History

In the fall of 2022, an act of Congress prevented an economy-shaking national rail worker strike. But what if the strike had happened? What would be the effect on specialty oil supply security? It may seem pointless to dwell over what-ifs instead of simply wiping the sweat from our brows and moving on. History tells us otherwise. This has happened before and could happen again in the future. So to ask “what if?” isn’t an idle mental exercise. It’s crisis planning. Learning from Rail Strikes In U.S. History On December 2nd, President Biden signed legislation blocking a strike of 115,000 rail workers that had been planned to begin on December 9th. It could hardly have been a closer call. Many rail strikes in U.S. history have often been successful in achieving their immediate goal: to slow the economy enough to bring attention to worker demands. The 1992 railroad strike of CSX transportation workers only lasted two days yet cost the economy about $2.1B. That would be far more in today’s dollars. In 2005, New York Transit workers struck. The event, featuring two days of mass confusion and damage to pre-Christmas retail business, was like a microcosm of what a modern national rail strike could look […]

Base Oil Updates – February

Our Observation US Markets for all intents and purposes have digested the recent postings announcement in early January. Buyers embraced the higher-than-expected reductions with open arms, yet many buyers remain cautious by not chasing the Major’s Spigots and filling their tanks with base oil to the brim. A sign of the times is being witnessed. Base Oil Demand in January was in general considered only firm while February thus far is experiencing global demand weakness. The usual buying spur that coincides with a dropping in base oil postings seem to be muted for a few obvious reasons and a few not so obvious. Out of the gate, 2023 feels more like a NORMAL seasonal slowdown of the past. Buyers typically come off of an end of the year run, reduce inventories some for tax reasons while others use it to reduce seasonal product slates and clear the deck to ready for the Summer Seasonal Production, thereby shifting products in March and early April for summer product runs. Since the onset of COVID we have not seen “normal” at least in the last 36 months. It appears that the market is attempting a retracing of the “old normal” buying patterns. Seasonal […]

Why Group II High-Viscosity White Oil Is the Future of Automotive Interiors

The oil industry has almost entirely moved beyond Group I oils. But certain gaps in specialty oil availability among Group II products have lingered, such as high molecular weight (MW), high-viscosity white oils. Reduced sulfuric content, resistance to oxidation, fewer impurities, and improved clarity have made Group II oils highly desirable in most contexts. The automotive industry is one example of an industry that is continually under pressure to adopt Group II products. But the highest molecular weight, or high viscosity index (HVI) process oils, which offer the lowest volatility, have historically been derived using the Group I process. Thanks to advancements in Group II refining, new very high MW, low-volatility products hold the key to achieving the automotive industry’s goals. (Learn more about our new high-viscosity white process oil, Renoil 2400-LV below.) Moving on from Group I (Bright Stock) High-Viscosity White Oil Much of the trend toward replacing Group I with Group II and III oils has been driven by the automotive industry, which has continually pushed for higher thermal/oxidative stability and better fuel economy from lower viscosity oils. That trend is only accelerating, driven in part by IMO 2020, the International Maritime Organization’s new limit on sulfur content in fuel oil. […]

Agricultural Spray Oil for Organic Farming: Renoil PSO 70 Earns OMRI Approval

Signal Fluid Solution’s PSO 70 agricultural spray oil is now approved for use for pest and plant disease control in certified organic operations under the USDA National Organic Program. This approval comes through the Organic Materials Review Institute (OMRI), a nonprofit organization that provides independent review of products against organic standards. As a paraffinic spray oil, PSO 70 offers superior purity at an ideal viscosity compared with traditional organic spray oil alternatives. In this article, we’ll answer key questions for agricultural product makers and organic farmers: What does it mean for a paraffinic spray oil to be OMRI Listed®? What rules apply to its use in organic farming operations? What are the benefits for organic farmers? What are the product specifications for Renoil PSO 70? 1. What does it mean for an agricultural spray oil to be OMRI Listed? OMRI determines the suitability of products for organic farming using one or more of three standards according to U.S., Mexican, and/or Canadian law. The U.S. NOP is the standard used for PSO 70 and all products produced in the U.S. Products fall into one of several use classes. Agricultural spray oil falls into the Crop Pest, Weed, and Disease Control category (abbreviated CP). This […]

Tire and Carbon Black Manufacturers: How to Control Carbon Black Dust

As important as carbon black is to tire makers and other industries, carbon black dust can be a serious problem. Controlling it is essential. The top concern is worker health. When exposure to carbon black dust exceeds OSHA regulations, workers can get seriously ill. And when emissions become a public issue, operations can be shut down, as was the case with Continental Carbon Company at the end of 2022. More on that story below. Furthermore, fugitive carbon black dust means product loss. It’s just another reason to make dust control a top priority, and specialty oil can help—as long as it’s the right oil. Why Controlling Carbon Black Dust Matters: Continental Carbon Company Continental Carbon’s story should be a cautionary tale for any industry that manufactures or handles carbon black. The plant had been serving the rubber industry as a carbon black producer since 1936. Their troubles began in 2007 when a federal jury awarded plaintiffs $19.5M in damages resulting from emissions from the plant. Complaints from local residents continued. Then, in 2022, the Alabama Department of Environmental Management found that the plant hadn’t made mandatory upgrades to its air pollution control systems. The plant was forced to shut its doors on December 31. This […]

From Crude to Your Base Oil Supplier: How Oil Prices Are Set

When your base oil supplier makes a pricing adjustment, what drives this change? It would be nice if the answer to this question was a simple summary of a few common reasons. But in reality, there are hundreds of factors that drive oil pricing changes, starting at the beginning of the supply chain: crude oil production. Factors that Drive the Price of Crude Base oil suppliers set pricing based in part on the price of our core raw material, crude oil. Though base oil pricing doesn’t fluctuate nearly as often as crude for the reasons explained below, significant trends do have a ripple effect throughout the supply chain. Many factors drive these trends. Some are predictable economic principles. Others are quite unpredictable, making crude oil among the most volatile commodities on the planet. Economic Factors Market speculators can make educated guesses about the direction oil prices will take by building models based on historical data and textbook economic principles. Supply & Demand In theory, as the global supply of any product increases or demand decreases, the price should go down; and as demand rises or supply decreases, the price should increase. Oil is somewhat subject to this basic law […]

The Growing Pharma TPE Market: How to Prepare Your Supply Chain (Starting with TPE Process Oil)

Demand for pharma applications is driving thermoplastic elastomers (TPE) market growth, making this a good time to bolster supply chains for polymers, TPE process oil, and other raw materials. The global TPE market is expected to grow at a compound annual growth rate (CAGR) of 7.1 percent through 2030, taking it from a value of $21.4M in 2022 to $39M by the end of the decade. As a top supplier for the TPE products industry, we want to make sure our partners have the products (e.g. TPE process oils) and logistics solutions to prepare for this growth. Pharma is Driving Market Growth in TPEs (and TPE Process Oil) We’re always watching the TPE industry closely to make sure we’re anticipating trends and serving our partners well. The following stories come to us courtesy of our friends at Rubber News. 1. DuPont has enlarged its single-use pharma TPE product lines. Driven in part by unprecedented demand for vaccine development during the COVID-19 pandemic, the corresponding demand for biopharmaceutical processing materials is also heightened. In response, DuPont launched its new pharma TPE tubing line Liveo in Q4 2021. TPE technology makes it possible to meet stringent requirements for purity, tensile strength, resistance to chemicals, […]

Electric Vehicles and the Future of Lubricants: A Base Oil Supplier Perspective

Analysts see the writing on the wall for the fate of the internal combustion engine (ICE), causing passenger car and heavy-duty motor oil (PCMO/HDMO) makers and their base oil suppliers to consider the implications for the lubricant industry. It’s far too early for anyone to panic. Though the pressure is on to innovate ways to reduce the environmental impact of ICEs, the tipping point into electric vehicle (EV) dominance is still several years away. But signs do indicate that this transition is a question of when, not if. Every PCMO/HDMO maker needs to start thinking seriously about how it can best serve the automotive industry of the future, and how its base oil supplier can support the evolution. The Rise of EV Will Bring Challenges “Adapting to EVs is going to be a challenge that will affect a significant portion of the (lubricant) industry …” – Nathan Shipley, Executive Director and Industry Analyst, NPD Group California ICE Ban The California Air Resources Board announced a ban on the sale of ICE vehicles by 2035, and as California goes, so may the rest of the U.S. soon after. So the clock is now officially ticking. This may force many lubricant makers to accelerate […]

White Oil Supply and the Future of Food Production: 4 Trends to Watch

As the food production industry strives to meet evolving consumer demands, specialty white oil supply will become increasingly critical. The global food market is expected to grow from about $2.3B in 2021 to nearly $5.2B by 2029, more than doubling in size. This growth will be driven by several shifts in consumer behaviors and expectations around health and environmental sustainability. And a key ingredient in all this will be highly refined, food-grade white oil. Food producers will see this decade of growth tied to the strength of their specialty white oil supply partnerships. 4 White Oil Supply-Dependant Trends in Food The food and beverage industry is watching many trends. Below are four of the most prominent trends in which winning and securing market share will require strategic partnerships with versatile white oil suppliers. 1. Safety and quality labeling. Many consumers are hyper-aware of the dangers of consuming foods that may have been inappropriately handled in production. Though cases are statistically few, recalls on meats, eggs, fruits, and vegetables (such as romaine lettuce) create the perception of danger. In response, consumers want to better understand where their food comes from. The savviest do their research. Many simply pay close attention to labels that indicate food is […]

3 “Secret” Ways Specialty Oil Suppliers Affect Your Bottom Line

As we all look back over the last few years of pandemic-era economics, it’s never been clearer how much the success of every business depends on the strength of its supply chain. And specialty oil suppliers can be particularly impactful. Signal Fluid Solutions staff recently gathered to discuss key strategies that affect the bottom line for specialty oil customers: manufacturers of synthetic rubbers, thermoplastic elastomers, agricultural products, personal care products, and many more. Below, we pull back the curtain to give you a behind-the-scenes look at three “secrets” about our industry that have a direct impact on your bottom line. (Though we admit they’re not so secret if we’re publishing them, of course.) The Impact of Specialty Oil Suppliers There’s nearly as much diversity among specialty oil customers as there is among the brands and consumers these industries serve. This is far from an exhaustive list: Automotive and Industrial Oil Manufacturers Food Manufacturers Agricultural and Household Product Manufacturers Rubber, Adhesives, Sealants, and Insulation Household and Sports Equipment What these industries have in common are hundreds of niche needs that major refiners aren’t prepared to fulfill directly. Specialty oil suppliers, like Signal Fluid Solutions, are essential intermediaries between customers and refiners, filling […]

Why Group II High-Viscosity White Oil Is the Future of Automotive Interiors

The oil industry has almost entirely moved beyond Group I oils. But certain gaps in specialty oil availability among Group II products have lingered, such as high molecular weight (MW), high-viscosity white oils. Reduced sulfuric content, resistance to oxidation, fewer impurities, and improved clarity have made Group II oils highly desirable in most contexts. The automotive industry is one example of an industry that is continually under pressure to adopt Group II products. But the highest molecular weight, or high viscosity index (HVI) process oils, which offer the lowest volatility, have historically been derived using the Group I process. Thanks to advancements in Group II refining, new very high MW, low-volatility products hold the key to achieving the automotive industry’s goals. (Learn more about our new high-viscosity white process oil, Renoil 2400-LV below.) Moving on from Group I (Bright Stock) High-Viscosity White Oil Much of the trend toward replacing Group I with Group II and III oils has been driven by the automotive industry, which has continually pushed for higher thermal/oxidative stability and better fuel economy from lower viscosity oils. That trend is only accelerating, driven in part by IMO 2020, the International Maritime Organization’s new limit on sulfur content in fuel oil. […]

Adhesives and Sealants Buzz: Silicone Shortage, Color Stability, Low Volatility Process Oil

As experienced process oil suppliers, we like to attend annual events like the World Adhesive & Sealant Conference. This year, the ongoing silicone shortage was definitely a dominant topic of conversation. But it certainly wasn’t the only issue that was top of mind for manufacturers. Three issues stood out last spring and continue to come up as frequent inquiries: Cost-effective solutions for extending silicone as the silicone shortage continues. Limited supply of a highly solvent (naphthenic), color-stable process oil to extend TPEs (thermoplastic elastomers) and for select products such as hot-melt adhesives. Rising demand for automakers to eliminate fogging caused by VOC’s (volatile organic compounds) with lower-volatility process oil. In this article, we provide a little information on the solutions we’ve been discussing, and about upcoming events where you can learn more. 1. Silicone Shortage: GTL Isoparaffins for Silicone Sealants Q: What is the best solution for extending silicone without losing elasticity and stability? Silicone’s unique properties are key to product quality in this industry. Some of the essential charateristics of silicone include: Keeps elasticity and stability in high and low temperatures. Resistant to other chemicals, moisture, and weathering. Compatible with more materials than most alternative polymers. Any material used to extend it must have a high degree of compatibility […]

Paraffinic, Naphthenic, Aromatic: How Rubber Process Oil Suppliers Hit the “Sweet” Spot

Process oil suppliers traditionally place most products into one of three categories, but these traditional indicators of color stability don’t always tell the whole story. In general, these categories cover the spectrum of desired qualities for use in rubber, EPDM and TPE (thermoplastic elastomer) manufacturing: Aromatic – dark, low color stability, great solvency Naphthenic – lighter in color, varying stability, intermediate solvency Paraffinic – lightest in color, high color stability, inert But for certain end products, engineers need to consult with process oil suppliers to consider unique solutions. Only the right mixture of characteristics will hit the “sweet” spot. The Challenge of Finding the “Sweet” Spot When selecting an appropriate extender, product engineers can choose from a variety of process oil products for certain end products within the proper category. Others have more exacting specifications. For these, we need to look beyond category to find the right point on the product spectrum. Matching End Product to Oil Category Examples of end product/process oil category matches that are generally acceptable include: Aromatic When color doesn’t matter, the high reactivity of aromatic process oils are acceptable. These include automobile tires, tread rubber, conveyor belts, and other applications where the color is typically black. (Automotive interiors […]

Specialty Oil Suppliers Applaud as Price of Crude Falls: Have We Hit the Top?

Early in the second quarter of 2022, we examined where oil prices might be headed and the downstream effects on specialty oil suppliers and customers. It appears we have good news. To briefly recap where we’ve been: Crude oil prices increased by nearly 60% throughout 2021, reaching an annual average of $68/barrel, the highest in three years, with a peak of $86/barrel. The Russian invasion of Ukraine in late February 2022 throttled supply, causing the spot price of West Texas Intermediate (WTI) to shoot up well above $100/barrel. As of April, gasoline prices, which had already been on the rise, were climbing still higher, setting a new U.S. record when the average cracked $5/gallon in June. In April, we looked at analysis of what the rest of the year might have in store. As pricing pressures were intensifying, would crude oil prices continue to rise, or was a decrease in store? Now, at the start of the third quarter, prices appear to be falling. But have we really reached the top of the pricing spiral? Can specialty oil suppliers, customers, and consumers expect some relief? Let’s see what analysts are saying now. Oil and Gas Prices in Early July 2022 For many, the […]

Is Your White Oil Optimal for Agricultural Product Production? 3 Applications to Test

White oil is an essential ingredient of most agricultural products, such as dust suppression products, pesticides, livestock health and other products. Quality white mineral oil makes all the difference in safety and optimal outcomes. Products with suboptimal or inappropriate oils can leave farmers, growers, grain elevator operators and others vulnerable to avoidable – sometimes dangerous – problems. A good agricultural (or horticultural) white mineral oil can help: Maintain a safe working environment for silo operators. Treat grain to limit dust hazards without harming its quality. Protect plants and crops from insects without causing sun damage. Maintain color stability for animal feeds, medications and vaccines. For these reasons and more, it’s essential that agricultural product manufacturers utilize white oils that are engineered with these applications in mind. 3 Reasons Why Oil Selection Matters in Agriculture The primary factors driving the performance of white oil in agricultural products are purity, viscosity and stability, each of which can vary dramatically from one oil to the next. The following applications illustrate the difference an optimal selection can make. 1. As a dust suppression agent, agricultural-grade white oil makes silo operations safer. As it is highly combustible, in fact explosive, grain dust is cause for serious concern among silo operators. […]

Entering a New Market? 5 Reasons to Consult Your Specialty Oil Supplier

If your company utilizes specialty oils in product formulations or in specialized product manufacturing, you’ve no doubt eyed opportunities to cross over into other industries. If you’re interested in entering a new market, read on. Whatever your industry: Rubbers and thermoplastics Food manufacturing Agricultural products Personal care products Pharmaceuticals Household products Automotive lubricants Or one of many others that specialty oil suppliers serve You’ve developed an intimate knowledge of the markets you currently serve. You know the precise product formulations, profit margins, supply and demand economics, and operational considerations. But how likely is it that you will see success when entering a new market based on that knowledge alone? What else might you need to consider? Entering a New Market: 5 Things to Consider According to Stephen Wunker of international consulting firm New Markets Advisors, these are the five key questions to ask before entering a new market. Quick or Slow (How quickly will this market grow?) First or Later (When is it best to move into this market?) Gaining a Foothold (Which customers should you target first?) Superhighway vs. Country Road (How should you break in?) Markets Next Door (Where is the best opportunity?) Using these five questions as a guide, […]

How to Justify the Cost of Food-Grade Oil Enhancement to Management

We’ve written before about the benefits of highly refined, pure food-grade oil as a production aid in a variety of industries. As an individual in your company in a position to influence operations management, you may already see the value of a product upgrade. The question is, how do you sell the idea to your management team? As discussed in Compoundings, the Independent Lubricant Manufacturers Association magazine, Noria Corporation recently published a white paper that addresses this very question. In “How to Cost Justify a Lubrication Program,” the author lays out some good points that apply broadly to manufacturing. Here’s our take, as consultants and suppliers of food-grade oils and other specialty oils and fluids. 3 Tips for an Effective Food-Grade Oil Presentation As a specialty oil supplier for four decades, Renkert Oil’s sales team has plenty of experience helping purchasers and product engineers navigate this scenario. To you, the value is as clear as water-white isoparaffins. But taking your pitch to the CEO is another matter. “Leaders who seek to achieve low-cost and/or high-quality output in mature markets will create a culture that is most receptive to lubrication excellence. Maintaining equipment more effectively through lubrication excellence is a long-term […]