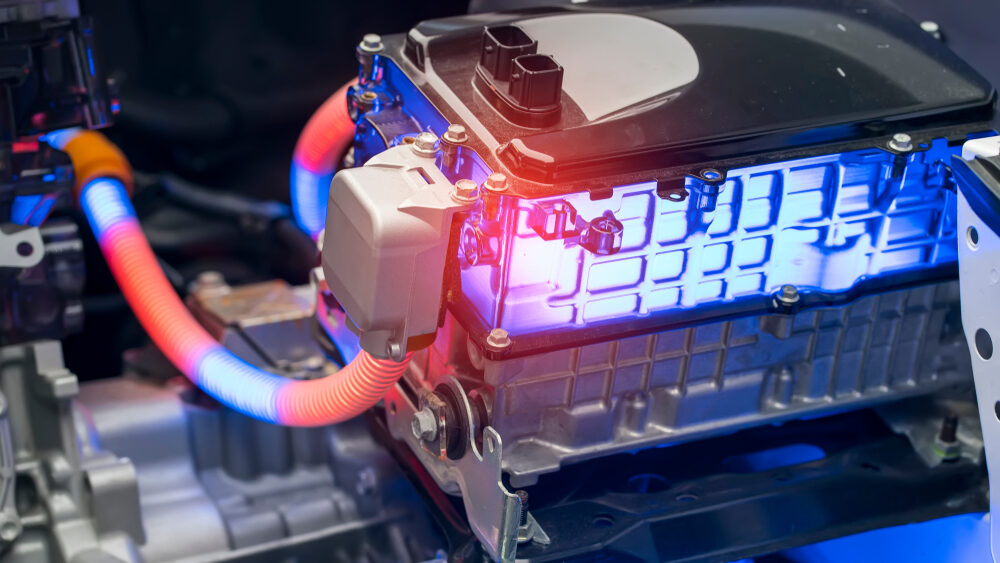

The internal combustion engine (ICE) is starting to give way to electric vehicles (EV) in terms of market share, and specialty oil suppliers are watching the shift closely.

Oil suppliers have long provided base products to lubricant makers. Now, the industry is beginning to invest more heavily in dielectric battery coolant fluids to support EVs.

For those of us in the oil industry, it’s important to think about how to prepare for this shift. Here’s a quick overview of where we are and how we’re preparing to evolve.

Evolve and Prosper: Specialty Oil Suppliers and Buyers

Lubricant companies are focusing more heavily than ever on thermal management fluids as a means to future-proof the industry.

EV fluid is developing into a highly competitive market.

“I think we realized that in the future the battery of a car will be almost what the engine was in the past … So it will be a center point of future mobility.” – Matthias Ostertag, Head of Global Business Segments, Fuchs Lubricants

Specialty oil suppliers like us want to be there for our customers in support of the shift. Thankfully, there’s enough precedent in specialty oils that we’re not starting from scratch.

Inspiration from Legacy Products

Transformer oils, or T-oils, have long served as an insulator and coolant for electrical systems. They offer a high flash point to prevent fires if overheated and provide oxidation stability to prevent corrosion and extend the life of transformers.

The concept of T-oils is a good starting point to explore the use of oils as EV battery coolant. The large lithium-ion battery packs that make EV travel possible require the same principles of thermal management and the electrical insulating quality of T-oils.

This isn’t to say that the same formulation will work for both applications. The challenge is to first select the best fluids on the market with the ideal properties for EVs, and then continually improve on these properties through new R&D:

- Low viscosity to flow between immersed batteries

- Very low electrical conductivity

- Very pure to prevent oxidation

Let’s explore the options.

Marketplace Options

The market currently offers several options. Let’s compare two: a traditional oil against a relatively new synthetic.

Conventional Naphthenics

Naphthenic oils have some good properties as a coolant, such as in refrigeration:

- Low pour point is ideal for cold temperatures

- Low viscosity index reduces flow as temperatures drop

- Low aniline point (solvency) can ensure contaminants dissolve and stay within the solution

However, naphthenic oils tend to be more volatile compared with isoparaffinic oils, a product category that’s gaining traction as a coolant fluid for reasons outlined below.

Synthetic Isoparaffins

Shell GTL isoparaffins are proving useful in similar applications, such as data centers.

Computer components used for high-demand data access are immersed in isoparaffins such as Shell GTL to effectively protect these components from disastrous overheating. Computers also perform better when kept cool.

Isoparaffins are chemically altered hydrocarbons that offer the stability of paraffinic oil while providing the high viscosity index ideal for coolant fluids.

- Synthetic

- Extremely low volatility and safe to handle

- High flash point, preventing potential fires

- Very high thermal stability

- High viscosity index so viscosity changes slowly with temperature

- Very pure, containing virtually no sulfur, nitrogen, or aromatics

- Non-corrosive

- Readily biodegradable and safe for the environment

While T-oils and naphthenic oils demonstrate how some version of conventional oil could be used as an EV coolant, synthetic isoparaffins like Shell GTL may be much closer to the right formulation.

Signal Fluid Solutions: Specialty Oil Supplier for the Future of the Lubricant Industry

As a proud supplier of a variety of specialty oils, we’re actively analyzing the market to determine how best to supply our automotive partners with EV fluids.

Shell GTL shows promise (in addition to its many current applications in personal care products, household cleaners and lubricants, production aids, and other product components.)

We’re excited to study possible future applications of specialty oils like these.

Our team here at Signal Fluid Solutions is always watching the trends, prepared to support our customers as they pivot into new products and markets.

Reach out to learn more about partnering with us. Let’s take on the future together with confidence.